Increasing demand for power is forcing power utilities to load power cables to their physical limit, and safety and efficiency concerns are making it more and more critical for operators to understand what is happening thermally both inside the cables themselves, and along the cable route.

Real Time Determination of Thermal Conditions along HV Power Cable Systems

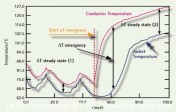

During high-load conditions and under emergency circumstances (such as when a failure occurs in a segment of the grid and power must be shifted to other sections to compensate) it often becomes necessary to load cables right up to the limits permitted by the relevant regulations. In these operational situations, it must be ensured that maximum temperature limits are not exceeded. Due to the increasing complexity of the thermal relationships along cable routes, the ability to continuously measure the temperatures along the cable has proven invaluable, providing critical operational data to engineers, especially in the case of a system faults such as a hot spots that could result in cable failure if they are not corrected.

The intrinsic temperature measuring system DTS based on LIOS Technology’s design, with fibre optic sensors either installed within the power cable’s cross section (FIMT – Fibre in metal tube ) or attached to the exterior of the cable, makes it possible to record the temperature profile along an entire cable route continuously, and to pinpoint the exact location of hot spots within a metre. Since the measuring principle employed is purely optical, the presence of electromagnetic influences, which can result in false sensor signals in other technologies, does not affect the DTS unit.

Distributed temperature sensing is a powerful tool that allows the accurate rating of high voltage power cables in real time, and provides the following operating benefits:

- Reduce power outages or blackouts

- Ensure continuity of supply

- Activate hidden capacity reserves of existing assets

- React quickly to overload conditions

- Conduct precisely and in real-time load predictions as new sources of energy are added to the grid

The temperature profile data, in any desired form or format, can be transmitted via standard interfaces from systems of the OTS product series as required, and be either displayed or further processed by PC, PLC or SCADA systems. As a result of the increasing demands placed on the ability to network and integrate measuring systems into management systems, LIOS offers network components that summarise DTS data from several DTS units and transport or convert it to the required network standards and protocols like Modbus, DNP3, IEC60870-5 or XML based data interfaces.

Dynamic Cable Rating

LIOS also provides an integrated Real Time Thermal Rating (RTTR) package via a well defined interface between its DTS data visualisation software and a commercialised – the industry’s de facto standard – cable ampacity program based on IEC standardised methods (mainly IEC 60287 and IEC 60853). Dynamic rating software couples the accurate temperature data provided by the DTS unit to predictive functions of cable ratings, providing engineers with even more information upon which they can base distribution and load decisions. The result is dramatically more efficient transmission of power, fewer “brown-outs”, and decreased operating costs.

For ADWEA’s /

For ADWEA’s /  LIOS Technology GmbH- Linear Optical Sensors is pleased to invite you to attend Power Indonesia 2009 – the 14th International Power Generation, Transmission and Distribution Exhibition, taking place 14-17 October at the Jakarta International Expo, Kemayoran.

LIOS Technology GmbH- Linear Optical Sensors is pleased to invite you to attend Power Indonesia 2009 – the 14th International Power Generation, Transmission and Distribution Exhibition, taking place 14-17 October at the Jakarta International Expo, Kemayoran.

info@lios-tech.com

info@lios-tech.com Follow LIOS on twitter

Follow LIOS on twitter info@lios-tech.com

info@lios-tech.com